Sie möchten über aktuelle Veranstaltungen des GWI informiert werden?

Melden Sie sich hier kostenlos und unverbindlich zu unserem Veranstaltungs-Newsletter an.

Sie möchten über aktuelle Veranstaltungen des GWI informiert werden?

Melden Sie sich hier kostenlos und unverbindlich zu unserem Veranstaltungs-Newsletter an.

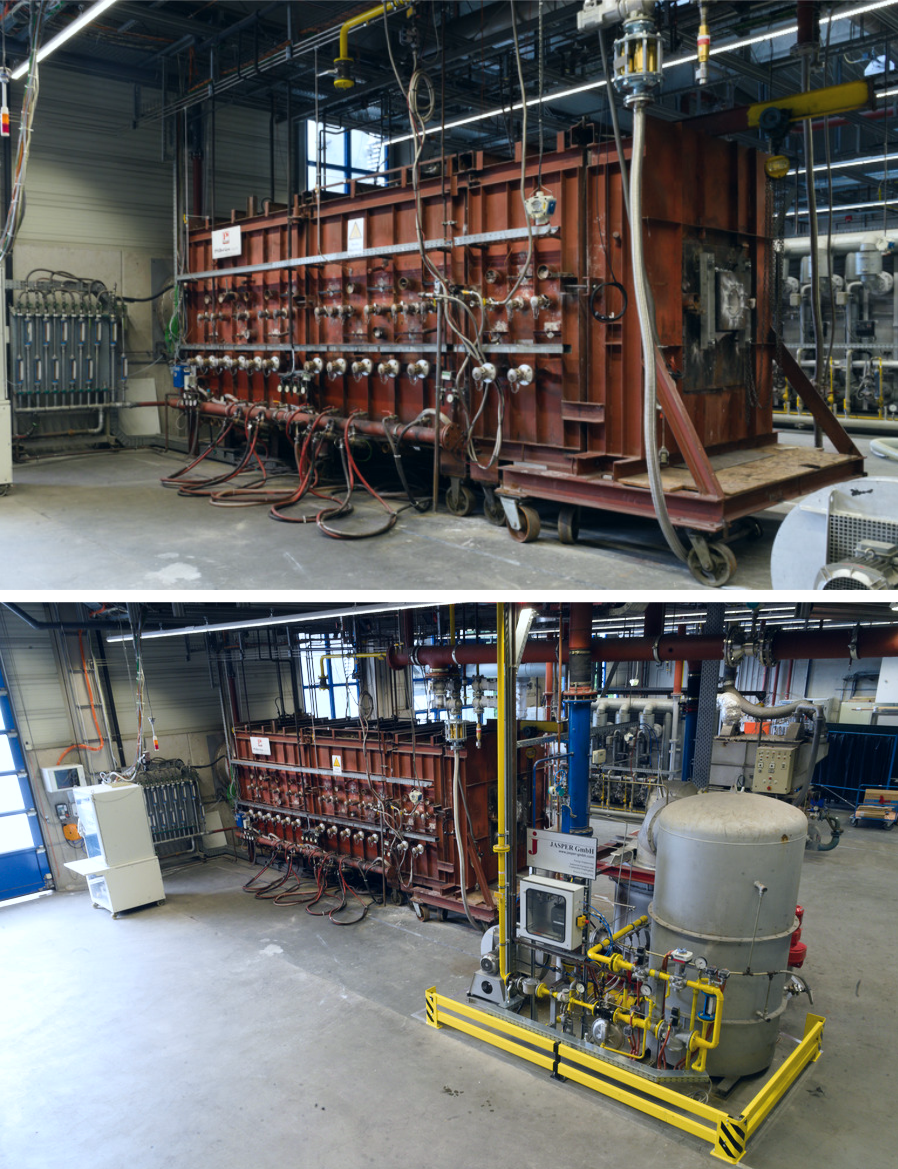

Test rigs and measurement equipment of GWI

For the experimental investigation of high-temperature combustion processes with high firing rates and strong air preheating, a high-temperature combustion test rig is available. This can be operated with various fuel gas compositions. Generous observation windows and smaller sampling ports provide access to the combustion chamber for both probes and optical measurement methods.

Typical operating conditions, as they occur in high-temperature processes, e.g., in glass melting furnaces, can be realistically replicated with the help of air preheating. A connected cooling system, consisting of variably usable, water-cooled stainless steel tubes, allows the furnace chamber temperature to be kept constant under various operating conditions. In the same manner, the furnace can also be operated in oxy-fuel conditions, I.e. using pure oxygen instead of preheated air, a very common combustion technology, especially in high-temperature applications.

For experimental investigations with lower firing rates of up to 300 kW and an air preheating of a maximum of 550 °C, GWI has another high-temperature combustion test rig at ist disposal , characterized by its particularly flexible application possibilities.

Additional indirect heating can beprovided by radiant heating tubes installed on the lower level of the test furnace and fueled with natural gas. This test system can thus be heated directly or indirectly up to 1,300 °C. The integrated air cooling system, located on the upper level of the test rig, ensures a constant furnace chamber temperature during investigations with variable operating conditions. A large observation window and several sampling ports also fully ensure accessibility for both optical and non-optical measurement techniquesin this test furnace.

Specially designed gas blending facilities for the high demands of test operation allow the production of synthetic blends in both small and large gas quantities. Depending on the required gas composition, tests can also be conducted with low-calorific gases at high firing rates. The controlof the respective gas volume flows is computer-controlled using modern mass flow controllers. Alternative fuels, such as hydrogen, ammonia, blast furnace gas, biogas, etc., can thus be tested under realistic process conditions, thereby enabling burner systems to be experimentally investigated in terms of their combustion and emission behavior.

In addition to measuring pollutant emissions in the stack, the high-temperature test rigs of GWI offer even more extensive methods for investigating combustion processes. With the help of water-cooled probes, both species concentrations and gas temperatures can be measured inside the furnaces themselves. Two-dimensional field measurements can thus create contour plots of temperatures and relevant concentrations (CO2, CO, UHC, NH3, N2O, NO, NO2, and O2) in the furnace chamber.

Another measurement technical method for evaluating combustion processes is UV flame visualization. Flame properties, such as flame shape, stability, or length, can be determined. In the "cold furnace", flames are clearly visible against the background of cold furnace walls. However, as the furnace wall temperature rises above 900 °C, the wall radiation in the visible spectrum is so great that the flames are barely or not at all distinguishable to the naked eye.

Furthermore, fuel gas and exhaust gas analysis devices and pressure probes for velocity measurements (Pitot tube, Prandtl probe) are available to complete the experimental investigations.

In addition, GWI has mobile measurementequipment and offers various services in the field of energy efficiency analysis, specifically for operators of thermal process plants, plant builders, and burner manufacturers. This includes, among other things, the experimental investigation of thermal process plants such as melting and heat treatment furnaces from various industrial sectors and scales. Both individual assemblies and complete systems can be included in the investigations.

A comprehensive energy efficiency analysis of a thermal process plant typically includes the steps:

With a thermal imaging camera, infrared images can be taken, and weaknesses and damages in the insulation of thermal processing plants can be detected earlier, increasing the safety and energy efficiency of these systems.

In addition to the short-term measurement of systems or their assemblies, we can also offer a variety of investigations as part of long-term measurement campaigns. The relevant data can be recorded at second intervals, if necessary, and digitally recorded over a period of several weeks. We process all the data obtained and present it in a clear form.

All our services are carried out by qualified engineers and technicians with extensive experience in the field of thermal processing plants and combustion technology.

Bildmotiv Seitenanfang: © GWI